Specification

- ऑटोमेशन ग्रेड

- Automatic

- स्पीड मोड

- शोर का स्तर

- Low (≤ 75 dB)

- परिचालन तापमान

- 0-40°C

- विशेषताएँ

- Easy Operation, User-friendly Control Panel, Corrosion-resistant Body

- फीडिंग सिस्टम

- Automatic Infeed Conveyor

- मशीन का प्रकार

- Butter Packing Machine

- गर्म करने की विधि

- Electric Heater

- फेज

- Single/Three Phase

- पावर सोर्स

- Electric

- फंक्शन टाइप

- फ़्रिक्वेंसी

- 50 Hz

- प्रॉडक्ट टाइप

- Butter Packaging Machine

- सामान्य उपयोग

- Industrial Butter Packaging

- मटेरियल

- टाइप करें

- क्षमता

- 1000-1500 packs/hour

- वजन (किग्रा)

- 780 kg

- उत्पाद का आकार

- कम्प्यूटरीकृत

- ऑटोमेटिक

- कंट्रोल सिस्टम

- इंस्टालेशन टाइप

- वोल्टेज

- 220-240 V

- पावर

- 2.5 kW

- आयाम (एल* डब्ल्यू* एच)

- Approx. 2500 x 1100 x 1800 mm

- कच्चा माल

- फ़ीचर

- रंग

Trade Information

- Minimum Order Quantity

- 1 Unit

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- हफ़्ता

About

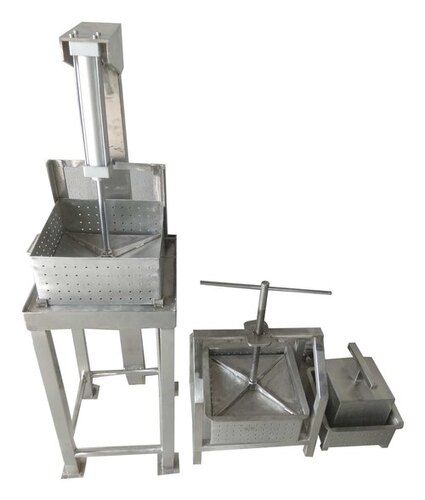

Butter Packaging Machine

उत्पाद विवरण:

Capacity 70 टुकड़ा/Min

Packaging Type Single

Automation Grade Automatic

Material stainless steel

Country of Origin Made in India

We, MEDH established in 2018 are manufacturing a qualitative range of Paneer and Cheese Cutting and Slicing Machine. Offered products range consists of Paneer Cutting Machine, Cheese Cutting and Slicing Machine, Noodle Cutting and Slicing Machine, Multifunctional Vegetable Cutting Machine, Etc. All offered products are manufactured using high-quality resources. Also, our cutting and slicing machine is famous due to their crack and damage resistance, high strength, strongly built, and affordable prices.

With sincerity and hard work of our professionals, we have carved a niche for ourselves in this domain by offering optimum quality paneer and cheese cutting and slicing machines. In adding to this, the organization has various facilities for the designing of excellent quality cutting and slicing machines.

Request

Callback

Versatile Packaging Solutions

This machine supports multiple packaging materials such as laminated films, parchment, and foil, making it adaptable for various dairy and food applications. Its heat-sealing system ensures a reliable and secure closure for every butter pack, while the automatic infeed conveyor and variable speed modes maximize throughput for both small and large-scale operations.

Cutting-Edge Automation and Safety

Equipped with a PLC-based control system and a digital touchscreen, the Butter Packaging Machine streamlines operations and facilitates quick changeovers in less than 15 minutes. Safety is paramount, with features like emergency stop, safety interlocks, and a corrosion-resistant body, safeguarding both operators and products in compliance with CE and GMP standards.

Efficiency and User-Friendly Maintenance

Designed to be low maintenance, the machine includes a spare parts and tool kit, allowing for easy upkeep. With a high level of output consistency and an operating noise below 75 dB, it remains unobtrusive in production environments, while computerized controls ensure precise, efficient operation.

FAQ's of Butter Packaging Machine:

Q: How does the Butter Packaging Machine maintain accurate pack weights?

A: The machine utilizes advanced PLC controls and precision feeders to achieve an output accuracy of 2 grams, ensuring each butter pack consistently meets specified weights between 100 grams and 500 grams.Q: What types of packaging materials can be used with this machine?

A: It is compatible with a wide range of materials including printed or plain laminated films, parchment paper, and foil, providing flexibility for various branding and protective needs.Q: Where is the ideal application for this packaging machine?

A: This packaging system is tailored for use in dairy industries and food processing units, making it suitable for industrial packing environments requiring hygienic, high-efficiency operations.Q: What is the process for changing product sizes or packaging materials?

A: Changing over to different product sizes or materials is streamlined and takes less than 15 minutes, aided by the digital touchscreen and user-friendly controls for quick adjustments.Q: What safety features are included with the Butter Packaging Machine?

A: It is equipped with an emergency stop button and multiple safety interlocks to ensure operator safety during operation, complying with CE and GMP safety standards.Q: What are the benefits of using this machine for butter packaging?

A: The machine offers hygienic, durable, and efficient packaging, high throughput (up to 1500 packs/hour), easy operation, and low maintenance, making it a cost-effective solution for industrial butter packaging.Q: How does the maintenance process work?

A: Maintenance is straightforward with the included tool and spare parts kits. The machine's stainless steel, corrosion-resistant body, and accessible design contribute to its low maintenance requirements.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+